E-mail:sales@chinaolivet.cn

A welding positioner chuck is a device that is used to hold and position a workpiece while it is being welded. It consists of a chuck, or clamp, that grips the workpiece and a motor that rotates the chuck to position the workpiece at the desired angle. Welding positioner chucks are typically used in conjunction with a welding positioner, which is a piece of equipment that rotates and tilts the workpiece to the desired position. The combination of the welding positioner and the chuck allows the welder to easily position the workpiece for welding, improving the accuracy and quality of the weld. Welding positioner chucks are commonly used in the manufacturing of heavy-duty structures, such as tanks, pressure vessels, and structural steel, where it is important to achieve precise, high-quality welds.

Our fixture welding chucks can also be adjusted for external or internal collet welding. Our welding chucks are designed for fast, self-centering applications. 3 jaw system allows for quick positioning along the slide bar.

Light weight and easy mounting.

Get bigger clamping range with extended jaws.

Adjusting shaft design easy to adjust clamping diameter.

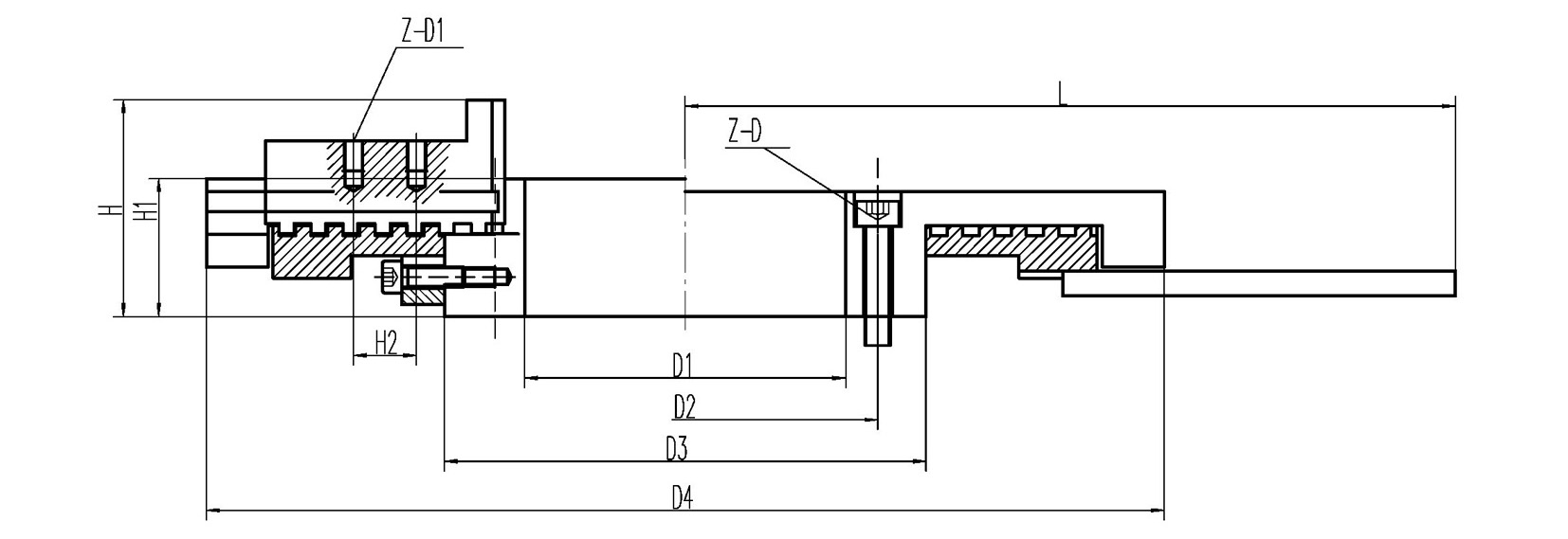

| Model | D1 | D2 | D3 | D4 | H | H1 | H2 | L | Z-D | Z-D1 |

| WP200 | 80 | 100 | 120 | 200 | 67.5 | 39 | 21 | 200 | 3-M8X35 | 6-M6 |

| WP300 | 100 | 120 | 150 | 300 | 67.5 | 39 | 21 | 240 | 3-M8X30 | 6-M6 |

| WP400 | 170 | 220 | 250 | 400 | 95 | 45 | 25 | 300 | 3-M10X40 | 6-M6 |

| WP500 | 240 | 280 | 320 | 500 | 110 | 60 | 25 | 350 | 3-M12X55 | 6-M6 |

| WP600 | 365 | 400 | 425 | 600 | 170 | 105 | 40 | 425 | 6-M12X110 | 6-M12 |

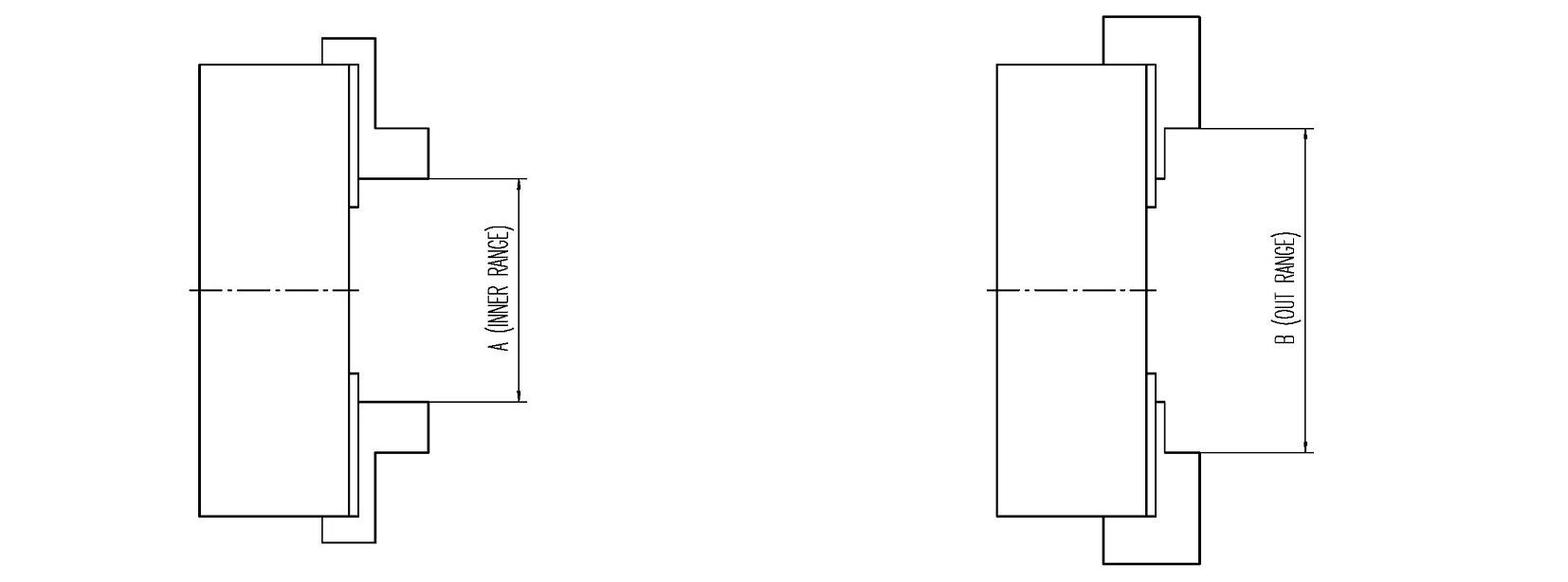

| Model | Weight | Load/ clamp capacity | Clamp Range (A) | Clamp Range (B) | Clamp range with add. Jaws |

| WP200 | 7kg | 80kg/ 200kg | Ø110-210mm | Ø 20-130mm | Ø5-300 mm |

| WP300 | 11kg | 120kg/ 250kg | Ø 170-280mm | Ø 80-190mm | Ø10-400 mm |

| WP400 | 24kg | 240kg/ 350kg | Ø 250-380mm | Ø 120-250mm | Ø20-500 mm |

| WP500 | 40kg | 600kg/ 800kg | Ø360-500mm | Ø200-340mm | Ø40-600mm |

| WP600 | 85kg | 1000kg/ 1200kg | Ø400-620mm | Ø150-410mm | Ø40-1500mm |

Workpiece Diameter: Models range from WP200 up to WP600, covering a broad range of internal/external diameters.

Load / Clamping Capacity: Each model supports different clamping forces and maximum load — for example, the WP500 can handle up to 800 kg clamp capacity, while the WP600 supports even larger sizes.

Extended Jaws Option: For larger or irregular components, extended jaws are available to expand the clamping range.

Mounting & Integration: Lightweight body and compact footprint ensure easy integration with welding positioners or rotators.

Pressure vessel / tank manufacturing — clamping cylindrical shells and components securely for welding.

Pipe fabrication — holding pipes of various diameters during circumferential or seam welding.

Structural steel & construction — for welding hollow steel sections, flanges or rings.

Heavy equipment manufacturing — when high torque and stable clamping are needed.

Clean regularly: Remove welding spatter and debris from the jaw surfaces after each shift.

Lubrication: Periodically lubricate the adjusting shaft and jaw sliding surfaces to maintain smooth operation.

Inspection: Regularly check for wear or damage on jaws and locking mechanisms.

Jaw replacement: Consider replacing or regenerating jaws when clamping accuracy degrades.

Rust protection: Apply a thin layer of anti-rust oil if the chuck is idle for long periods or in humid environments.

Always verify that the workpiece is centered and properly clamped before starting rotation.

Use the correct lever or tool for opening / closing jaws — avoid forcing them.

When rotating, gradually ramp up to the required speed to avoid shock loads.

If working with very heavy parts, ensure the mass and distance from chuck face do not exceed the rated torque or load — improper loading can cause instability.

Train operators on emergency stop procedures and periodic safety inspections.

Wuxi OLIVET Machinery Equipment Co.,LTD.E-mail: sales@chinaolivet.cnTel: +86-510-8383 0908

Home About UsProductsQuality ControlCompany NewsContact Us Sitemap

Copyright©2015 Wuxi OLIVET Machinery Equipment Co.,Ltd. Technical Support: Reanod