E-mail:sales@chinaolivet.cn

OLIVTE has a comprehensive range of pipe rotator for automatic welding. These very versatile handling tools enable welding to be carried out in the optimum positions to benefit the quality of the work. They are engineered with durable materials and advanced control systems, ensuring long-term reliability even in harsh industrial environments.

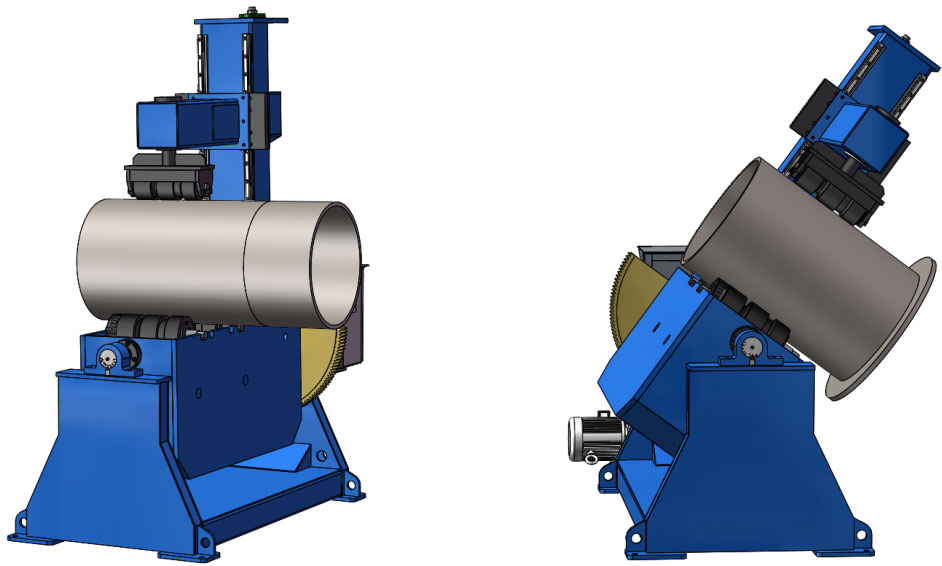

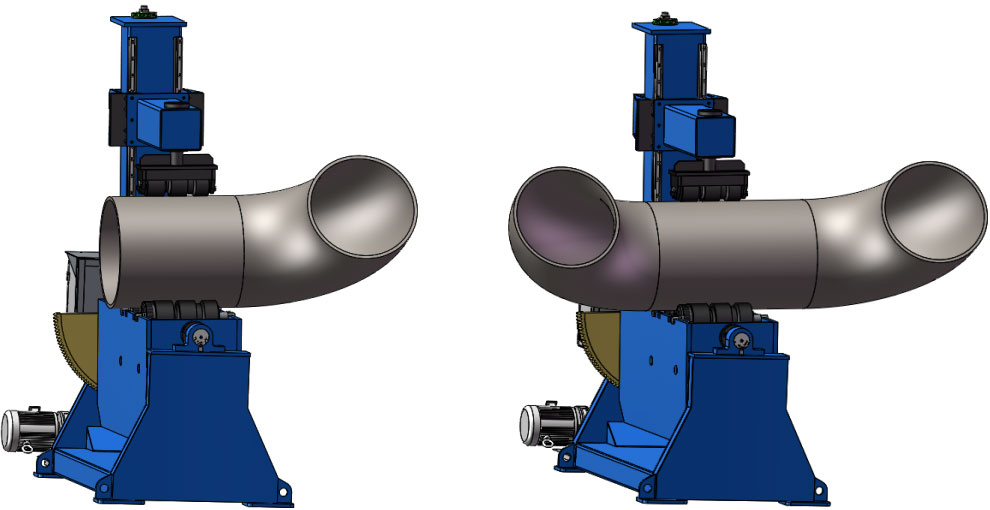

YGHB Series pipe rotators are ideal solution to solve the problem of rotating and tilting demands on pipes or flange welding. Height, angle and speed are all adjustable. A motorized slide with oscillator optional can be to realize automatic welding. This adaptability makes them suitable for both small-batch customization and large-scale mass production scenarios.

Our welding rotators, tank rotation rolls and pipe rolls maximize safety, minimize handling, increase productivity and improve consistency and weld quality on cylindrical vessels. From small diameter pipes to huge monopile structures for wind tower turbines. Additionally, they support seamless integration with other welding equipment, allowing for a fully automated production line that further enhances operational efficiency.

A. 1 Main frame body

B. 1 Electric control system

1 control panel

1 foot switch

| Model | YGHB-03 Pipe Rotators |

| Max Loading capacity | 300 kg (Approximately 2204 lbs. meets most pipe welding job requirements.) |

| Pipe/ Flange diameter | Φ50-500 mm |

| Roller linear speed | 100-1000 mm/min |

| Rolling speed adjustment | DC speed regulator |

| Roller motor power | 120w |

| Max. rolling torque | 120 N.m |

| Tilting angle | +/- 45° |

| Tilting speed | 0.3 rpm |

| Tilting control | By manual |

| Elevating control | By manual |

Ask us any questions you may have about your specifications. The important thing is that we are a physical factory and we accept custom orders! That's a better price and better after-sales guarantee than some big name dealers!

A pipe rotator is a device that is used to rotate a pipe while it is being welded. This allows the welder to easily access all sides of the pipe and produce a high-quality weld. Pipe rotators can be used in a variety of welding applications, including welding pipes in the field, in a workshop, or in a fabrication shop. There are several types of pipe rotators available, including manual rotators, hydraulic rotators, and pneumatic rotators. The type of rotator that is best suited for a particular application will depend on the size and weight of the pipe being welded, as well as the welding process being used. Modern pipe rotators also often feature digital controls and remote operation capabilities, enabling welders to fine-tune rotation parameters for even greater precision and ease of use.

Yes, pipe rotators can be used for welding. Its primary use is to assist and complement the welding process. It’s what you can use to hold a round or cylindrical workpiece and move it in a whole 360-degree rotation. This allows the welder to easily access all sides of the pipe and produce a high-quality weld. Moreover, they can be integrated with various welding techniques such as MIG, and submerged arc welding, ensuring compatibility with diverse manufacturing needs. Additionally, their adjustable rotation speed and torque make them suitable for both thin-walled and thick-walled pipe welding applications.

You can use pipe welding rotators for a wide range of pipe and tube fittings.

Here are some of the most common ones:

Long Radius Bend Pipes

Elbow Pipes

Tee Pipes

Flanges

Wye Pipes

And Many More!

Note: Pipe welding rotators assist the welding process, so big and heavy parts and components are loaded to these machines more often than not. But, you can also use it for small to medium-sized pipes and workpieces.

Pipe welding rollers are devices that are used to support and rotate pipes during the welding process. They are typically used in conjunction with a pipe rotator and are designed to make it easier for the welder to access all sides of the pipe. Pipe welding rollers are typically made of durable materials such as steel or aluminum, and they come in a variety of sizes to accommodate different sizes of pipes. Some welding rollers are adjustable, which allows them to be used with a range of pipe diameters. Other features that may be available on welding rollers include locking mechanisms to hold the pipe securely in place, and protective coatings to prevent the pipe from being damaged during the welding process.

Our range of pipe rotators is designed to enhance efficiency and precision in welding operations. Whether you need a pipe welding rotator or a fully automated pipe rotator machine, our products cater to various industrial requirements. For seamless operations, we offer pipe rotators for welding, ensuring stability and accuracy throughout the process. Our selection includes high-performance welding pipe rotators and pipe rotator for welding systems, suitable for both small-scale and large-scale projects. If you're looking for reliable equipment, our welding rotators for sale include options like the automatic pipe roller for welding, delivering unparalleled convenience and quality.

Using pipe welding rollers for welding can give you the following benefits and advantages:

Faster and Speedier Production

Your pipe rotators can help you get even to the most awkward and complicated parts. This makes production faster, more urgent, and hastier.

Stable and Consistent Welds (For Bulk Welds)

Pipe rotators can set your workpiece in place without it being misaligned. What does this mean for you?

Whenever you perform the weld, the rotator can move it more consistently with more stability; this makes all your welds the same without any irregularities.

Safety and Security of Welders

Using pipe rotators dramatically increase the safety and security of your welders. It has been proven and tested.

Higher and Better Quality of Welds

Your welders wouldn’t anymore worry about how to handle the workpiece. With this, they can focus on the welding procedure itself, creating better and higher weld quality.

Cost efficiency in the long run

By reducing material waste from faulty welds and minimizing labor hours, pipe rotators help lower overall production costs, delivering a strong return on investment over time.

Enhanced adaptability to diverse workpieces

They can accommodate a wide range of pipe diameters and weights, eliminating the need for multiple specialized tools and making them a versatile addition to any welding operation.

There are a few potential disadvantages to using pipe welding rollers:

Cost: Pipe welding rollers can be expensive, especially if you need a large number of them or if you need rollers that are capable of handling very large pipes. Ask us for requirements and prices!

Complexity: The setup and use of some pipe welding rollers can be complex, which can add to the overall time and effort required for a welding project. Our pipe welding drums are simple to set up and easy to get started with.

Limited flexibility: Pipe welding rollers are typically designed for use with a specific range of pipe diameters, so if you need to weld pipes that are outside of that range, you may need to purchase additional rollers or use a different type of support.

Limited stability: Depending on the design of the rollers, they may not provide as much stability as other types of pipe supports, which can make it more difficult to achieve a high-quality weld.

Maintenance demands: Regular upkeep, such as roller replacement and lubrication, is neccessary to ensure optimal permance, which can incur additional time and cost over the equipment's lifespan.

Overall, the advantages of using pipe welding rollers may outweigh these disadvantages in many cases, but it's important to carefully consider your needs and whether rollers are the best solution for your particular welding project.

Many industries can find the use of pipe rotators beneficial. But among the most common that utilize it are:

Metalworking and Fabrication Industry

Construction Industry

Oil & Gas Industries

Petrol Chemical Industry

Power and Generation Industries

Nuclear Industry

Industries that utilize heavy pipes and tubes often find the best use for it. But, it can also be used in the automotive industry (i.e. creation of tanks, etc.).

Would the rotator meet the capacity requirement of the load?

Is there a specific speed for power or turning for any of the projects?

What specific type of wheels do I need?

How big would the workpieces be? How many rollers would I need?

A turning roll is a machine that helps handle heavy materials (more than 100 tons).

Get more detailed parameters or pictures!

If you are looking for a rotary table for welding, a low cost rotary tube welder or accessories, then you have come to the right place. olivte specializes in quality rotary welding tables, orbital welders, turntables and accessories.

Olivet's column and boom welding manipulator could be assembled to automatic welding system with the welding turning roll, automatic welding machine, welding control system, etc. It's widely used in boiler, pressure vessel, chemical petroleum, metallurgical construction, and machinery.

Wuxi OLIVET Machinery Equipment Co.,LTD.E-mail: sales@chinaolivet.cnTel: +86-510-8383 0908

Home About UsProductsQuality ControlCompany NewsContact Us Sitemap

Copyright©2015 Wuxi OLIVET Machinery Equipment Co.,Ltd. Technical Support: Reanod