E-mail:sales@chinaolivet.cn

OLIVTE specializes in the production of an innovative growth line system for the rapid alignment, leveling, assembly and indexing of large pipes, tanks and vessels. Weights up to 100 tons. The Growline reduces assembly time by 65%, minimizes crane operations, and maximizes operator safety compared to conventional methods.

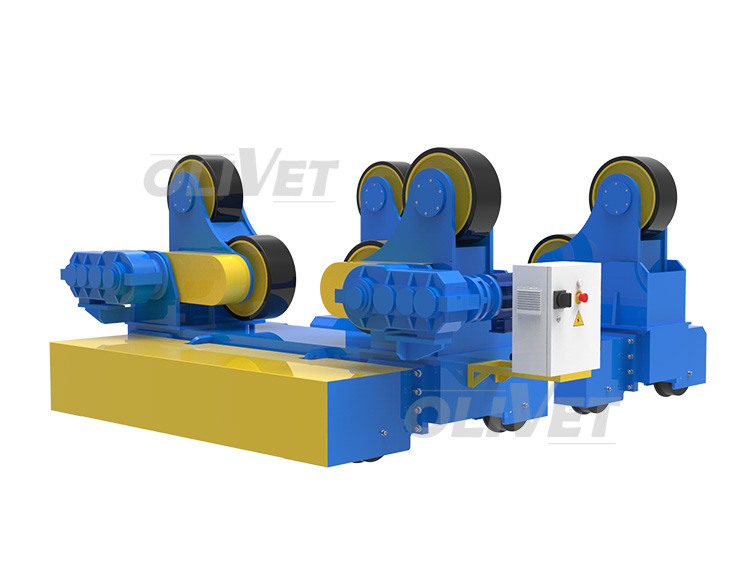

FITA Series shell Growing Line is used for three or more pipes/ shells assembly and welding job. FITA Growing Line is equipped with two fit-up self-alinging roller beds, which have four independent hydraulic height adjustment rollers, to ensure the assembly and welding job speedy with a high performance.

A. Fastest system to assemble 1+1 or 1+1+...+1 sections

B. Self-aling design automatically to meet different diameters of workpieces

C. Four independent hydraulic adjusting roller to align the two sections with each other

D. European hydraulic station, Parker oil tube and Schneider elctrical control system

E. Ideal for:

- Wind tower fabrication

- Pressure vessels

- Pipe assembly

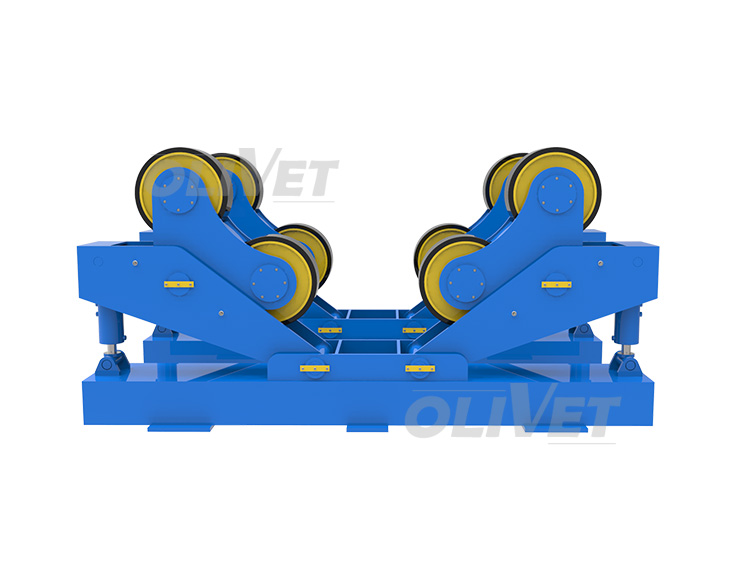

Rotator A & B: Hydraulically adjusted idle rotator which fixed on ground and has two hydraulic cylinders to adjust center distance of rollers separately.

Growing section is for ‘growing job’ consist of two rotators.

Rotator C: Idler rotator- Automatcially adjust supporting angle of rolls to handle different workpiece diameter and manual travel on rail.

Rotator D: Power rotator - Automatcially adjust supporting angle of rolls to handle different workpiece diameter and motorized travel on rail.

.

A. 1 Power section, 1 Idler roller bed

B. 2 Fit up roller beds and hydrulic station

C. 1 Hydraulic support v-roll

D. 1 Electric control system

1 Main control panel

2 Remote pendant

Model | FITA-60 | FITA-80 |

Max loading capacity | 60 tons | 80 tons |

Rotator A & B capacity | 30 tons | 40 tons |

Rotator C and D capacity | 60 tons | 80 tons |

Workpiece diameter | Ø 1800- Ø 5000 mm | Ø 2000- Ø 5500 mm |

Rollers supporting angle adjusting mode | Auto Self-aligning | Auto Self-aligning |

Rotator A & B roller height adjusting | Hydraulic cylinder | Hydraulic cylinder |

Hydraulic control mode | 4 each separately | 4 each separately |

Rolling speed | 100-1000 mm/min (VFD) | 100-1000 mm/min (VFD) |

Rolling motor power | 2 X 2.2 kw | 2 X 3 kw |

Roller material | Polyurethane (PU) | Polyurethane (PU) |

Rotator D horizontal moving speed | 250-2500mm/min (VFD) | 250-2500mm/min (VFD) |

Rails inner gauge | 1800mm | 2000mm |

You are very welcome to consult with us from Europe, USA and other countries and regions!

Wuxi OLIVET Machinery Equipment Co.,LTD.E-mail: sales@chinaolivet.cnTel: +86-510-8383 0908

Home About UsProductsQuality ControlCompany NewsContact Us Sitemap

Copyright©2015 Wuxi OLIVET Machinery Equipment Co.,Ltd. Technical Support: Reanod