E-mail:sales@chinaolivet.cn

With the significant growth of the welding industry, one of the biggest debates in the industry has emerged: Which is better, automatic, or manual welding? Nowadays, some people may think automation is better than manual methods, others think the opposite, and some people say that implementing both methods in the store is ideal.

When choosing the welding method to be implemented in the workshop, many factors must be considered, such as productivity, budget, project size, etc. But first, the auto welding positioner manufacturer clarifies the difference between the two welding methods.

There are two types of automatic welding, but, usually, most of the welding operations are done by welding equipment. The existence of humans has two functions: either to operate the machine or to observe the entire welding process while ensuring that the machine is working properly.

This method used to be only suitable for large-scale welding operations, such as the mass production of pipelines and automobiles, but as companies understand the benefits of welding automation, small and medium-sized enterprises have also turned to weld automation.

At the same time, in manual welding, the manual welder performs the welding operation by himself, and the quality of the product largely depends on his skill. This is the ideal choice for beginners, professional DIY workers, and small businesses that only need small-scale welding operations.

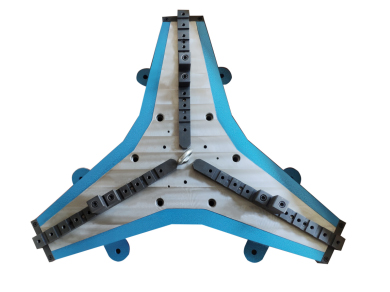

Welding Chuck

The output of automatic welding is at least twice that of skilled welders and manual welding. It also allows you to repeat the welding cycle without affecting the output quality. But you cannot rely solely on the work of five welders to rely on the automation system. After all, machines are still prone to malfunction or breakdown.

At the same time, in manual welding, you must consider the welder's abilities-how long he can perform welding without being overworked, whether the welder can complete the task consistently, what to do if the welder is sick, etc. Skilled welders can cost-effectively provide the almost perfect output of consistent quality and quantity.

Automatic welding has a uniform speed and process and can produce products of the same quality. However, for smaller touch-up paint, this may not be an ideal choice. A human welder can simply perform a quick torch in the area that may be missed.

Nevertheless, manual welding may still have common quality problems, such as the formation of welding spatter, pores, and shallow penetration.

The automation system is built for any possible adjustments you need to make to suit your welding operation. With built-in swivel casters, they also provide convenient mobility. But in terms of transferring from one welding operation to another, it may take longer for you to adjust the automaton to another welding cycle.

On the other hand, manual welders can easily transfer from one workstation to another to perform different welding tasks. The manual welding machine may take longer to move, but in terms of completing different welding in a limited time, manual welding is more ideal.

The automation system can save you a lot of labor and production costs. You don't need to hire highly skilled welders to get the job done-people who can operate the automation system are enough. Since fewer human resources are required, the possibility of human error can be reduced and the amount of production waste can be reduced.

Investment in automatic welding machines can be very expensive, especially for start-up companies. Although there are some budget-friendly options to switch to welding automation, some people may still find that the initial investment is higher than the investment in manual welding operations. But in the long run, you can enjoy the cost-effectiveness of welding automation.

For start-ups, small businesses, and businesses that do not require large-scale welding operations, manual welding may be an ideal budget option. You only need to invest in manual welding machines, some welding materials and skilled welders. Compared with the cost of the automation system, the total amount of these investments is small.

But in the long run, you may find it as expensive as welding automation. There are labor costs, maintenance, and production waste costs. Not to mention an emergency in your store, such as your welder having an accident during the welding process.

In the final analysis, it all depends on your business plan. Do you plan to double production in the future to serve more customers? Do you plan to reduce costs without sacrificing quality and output?

If you want the best investment and bring more revenue to your business, then welding automation is worth it! We can help you automate welding operations without compromising your budget.

Wuxi OLIVET Machinery Equipment Co.,LTD.E-mail: sales@chinaolivet.cnTel: +86-510-8383 0908

Home About UsProductsQuality ControlCompany NewsContact Us Sitemap

Copyright©2015 Wuxi OLIVET Machinery Equipment Co.,Ltd. Technical Support: Reanod